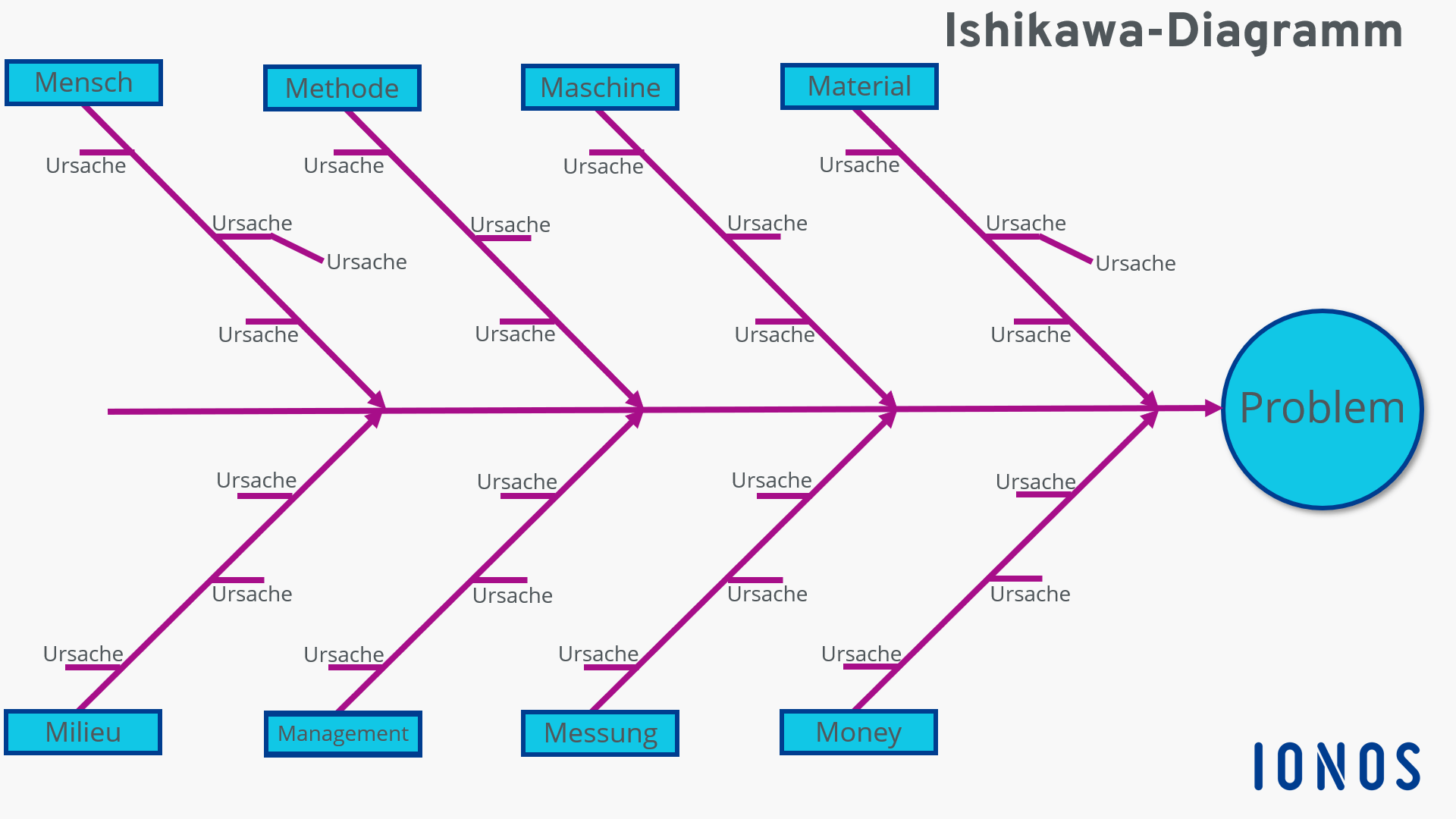

Exploring this questioning can shed light on the first indications to ratify the arguments of Ishikawa and Deming, that the main problems of companies are found in their processes and perhaps, in a deep way, in some of these cornerstone root causes that have to do with the way organizations are managed. Organizations across a variety of industries, including manufacturing, healthcare, and service use. It is named after Japanese quality control expert Kaoru Ishikawa, who developed the concept in the 1960s.

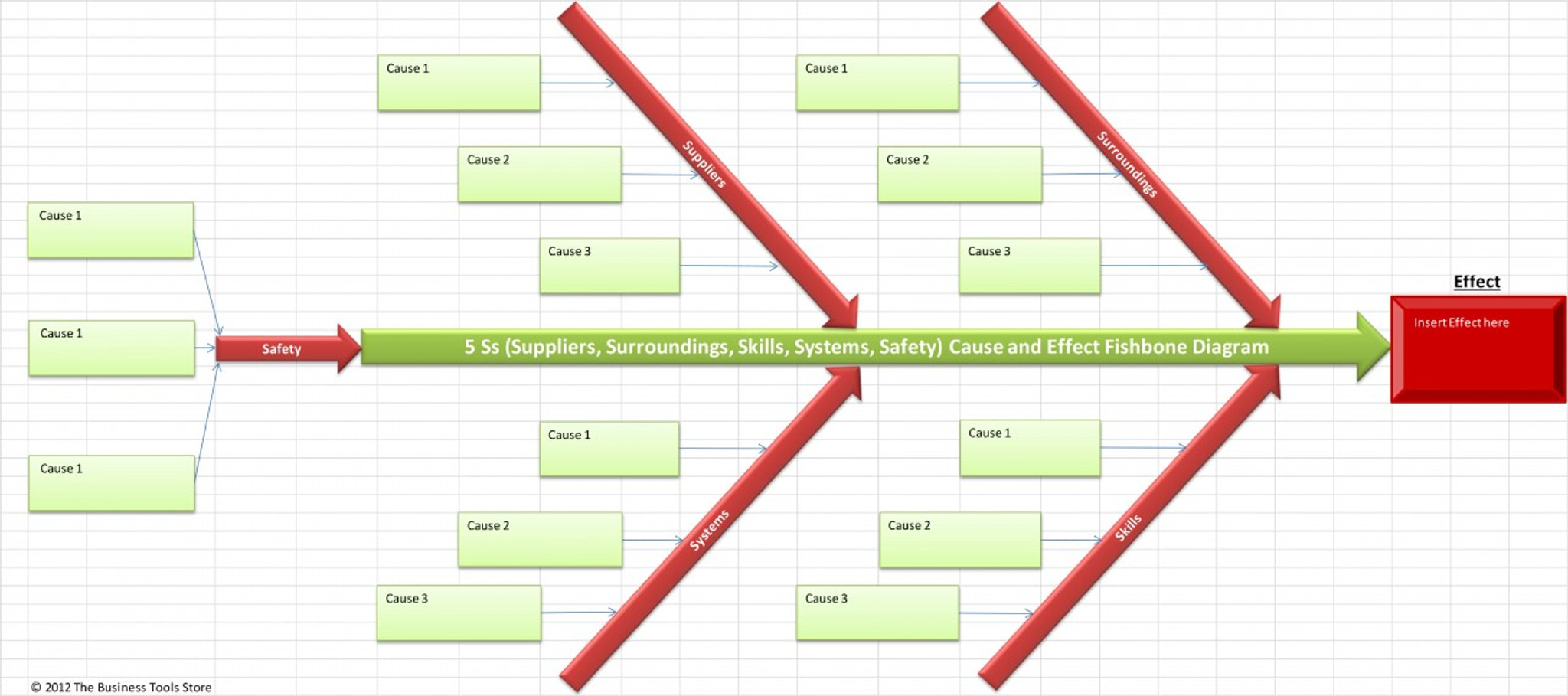

In this group of quality tools is the cause-and-effect diagram (CED), also known as “The Fishbone” and “Ishikawa diagram”. A fishbone diagram, also known as an Ishikawa diagram or cause and effect diagram, is a tool used to identify the root causes of a problem. It divided all the possible causes into three. Kaoru Ishikawa proposes seven basic quality tools. Liliana (2016) presented a novel model of Ishikawa diagrams for the assessment of non-quality problems in dealing with part precision evaluation. Some of these efforts use quality control tools to remedy it. The elimination of problems and waste (MUDA for the Japanese) plays a fundamental role in the reduction of operational costs and quality rejections of finished products both internally in the organization and in the supply chain. Some manufacturing and service organizations have made efforts to work on continuous improvement in the form of Kaizen, lean thinking, Six Sigma, etc. A new model of Ishikawa diagram for quality assessment Authors: Liliana Luca Constantin Brâncusi University Abstract The paper presents the results of a study concerning the use of the.

0 kommentar(er)

0 kommentar(er)